Items filtered by date: December 2014

Internet Explorer Corrupted Default Search Provider

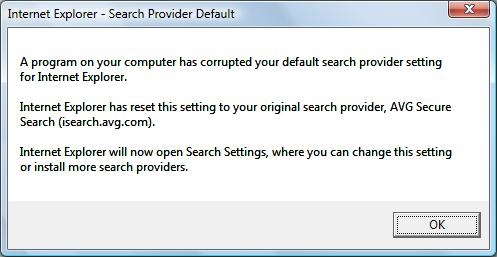

Do you keep getting the following error when you open Internet Explorer even after you have restarted IE.

"A program on your computer has corrupted your default search provider setting for Internet Explorer"

Solution

I uninstalled AVG Secure search. If AVG Secure Search is not in the add remove list, Install AVG Secure Search and then uninstall it.

Other Resources

- AVG Secure Search

- Default search provider corrupted?| Internet Explorer Dev Center (Microsoft)

"For the record, I was experiencing the same issues and the suggestion of "deleting both

HKCU\Software\Microsoft\Internet Explorer\SearchScopes and

HKCU\Software\Microsoft\Internet Explorer\User Preferences"

worked for me! Thanks, AlexGI and good luck, JoachimJ!!!" - a program on your computer has corrupted your default search provider - Windows 7 Help Forums

- A program on your computer has corrupted your default search - Microsoft Community

a.Make sure IE 8 is closed then navigate to registry key: HKEY_CURRENT_USER\Software\Microsoft\Windows\CurrentVersion\Explorer\User Shell Folders

b.Add a new “Expandable String value” inside the above mentioned key with a value name of “AppData” and a value data of “%USERPROFILE%\Application Data”.

c.Reopen IE 8 and see if you still get the error message

the reg key was present (a. b. above),

i set bing to default search. avg search was default, i cannot delete the avg search so i am uninstalling the toolbar AVG Security Toolbar

Updaters and Online Scanners

Software Updating / Repository Sites

- Filepuma (glarysoft)

- FileHippo

- software.informer.com - like filehippo

- CNet's Download.com

- Windows Update (dough!!)

- FileHorse.com

- FossHub - seems only for Open Source

Software Updater Applications

- Secunia PSI

- Bullguard – built in

- CNET's Download App (Previously TechTracker)

- PatchMyPC.exe - can install updates and ad software automatic. - Patch My PC is a small portable application that updates third party

- Major Geeks SoftwareUpdater

- Glary utilities (uses filepuma)

- software.informer.com

- shows you all of your apps not just the out of date ones

- this is now all controlled in the app

- there are descriptions of the app on the righ and review

- the app requires admin privaledges to run. a note is that if you primary account is not an administrator account you will be prompeted to enter an adminstrator accoutn details and the filehippo app will set the default download directory in that admin accoutn and not yours

- can schedule frequent scans

- can select which apps you check for updates

- FilePuma Update Detector

- FileHippo Update Checker (UDC)

- easy to use

- some programs you can download and run, but some just download. I think this might be an issue in the app. Generally the first app you select you can download and run. the rest in the que will just download.

- if you download more than 1 program, they will all download but on the first one will run automatically

- when the program is download the button in the list will change to run

- the app requires admin privaledges to run. a note is that if you primary account is not an administrator account you will be prompeted to enter an adminstrator accoutn details and the filehippo app will set the default download directory in that admin accoutn and not yours

- file hippo downloads the files to a specified folder and they remain after install.

- can be run on startup

- can schedule frequent scans

- Avast Antivirus - inbuilt to the antivirus software

- SUMo Lite (Software Update Monitor) - can also do drivers, requires DUMo

- AppFresh for Mac

- Update Notifier

Articles

- Best Free Software Update Monitor | Gizmo's Freeware

- FileHippo Update Checker vs. Update Notifier vs. SUMo | 40Tech

Driver updaters

- IoBit Driver Booster 3 (free and paid)

- Dell

- ASUS live updater

- Intel

- MSI

- Intel Driver Update Utility

- Microsoft

- Nvidia

- ATI AMD

- AMD Driver Autodetect

- Dell

- DUMo Lite (Drivers Update Monitor)

- DriveTheLife - Rated ok by The Windows Club

Online AV Scanners

- http://www.eset.com/us/online-scanner/

- http://www.avg.com.au/resources/web-page-scanner/t1/

- http://quttera.com/website-malware-scanner

- http://online.drweb.com/

- http://onlinelinkscan.com/

- http://housecall.trendmicro.com/uk/

- http://www.f-secure.com/en/web/home_gb/online-scanner

- http://www.bitdefender.com/scanner/online/free.html

- http://housecall.trendmicro.com/uk/

- http://www.makeuseof.com/tag/10-free-online-malware-and-virus-scanners/

Browser Security Toolbars

- panda AV has a toolbar

- mcaffee has a site advisor

- avira does a web protect toolbar

- avg link scanner - http://www.avg.com/gb-en/secure-search same?

- http://www.bitdefender.com/solutions/trafficlight.html

Website Scanners

- http://sitecheck.sucuri.net/

- http://app.webinspector.com/ by comodo

- https://www.virustotal.com/uk/

- http://quttera.com/website-malware-scanner

- http://scanurl.net/

- http://www.freedrweb.com/for+web+sites/?lng=en

- http://urlquery.net/

- http://www.qualys.com/forms/freescan/?leadsource=5545965&kw=scan%20website%20for%20malware%20online&gclid=COP-xM7go78CFQsEwwodlJQApQ – might be a fiddle on this

- http://www.unmaskparasites.com/

- http://sitecheck.sucuri.net/results/quantumwarp.com - can fingerprint joomla

- Website Reputation Checker Tool - http://www.urlvoid.com/

- https://www.trustedsource.org/?p=mcafee

- http://uitest.com/en/check/

- http://onlinelinkscan.com/

- http://scanner.pcrisk.com/

- http://www.hackingarticles.in/best-of-hacking/best-online-website-scanner/

- Comodo PCI Compliance Scan

Other Scanners

Other Browser Security addons

- http://privdog.com/ add management plugin (part of comoodo installer)

- http://www.ghostery.com/ - tracking blocker and other shit

Lots of links on this page

- http://www.alken.nl/web-security-check.htm - lots of stuff here

- http://forum.sysinternals.com/free-online-security-scans-for-suspicious-url-link_topic22045.html

- http://www.malwarehelp.org/freeware-open-source-commercial-website-security-tools-services-downloads.html

- http://forum.thewindowsclub.com/windows-security/33855-online-url-scanners-scan-websites-malware-virus-phishing-etc.html

- http://cleanbytes.net/malware-online-scanners

- http://www.microsoft.com/security/scanner/en-us/default.aspx - is this still going

- Safety scan – in results has links to loads of saftery scanners - http://www.urlvoid.com/scan/crowshotel.co.uk/

Sound not working in Windows 8 - 'Error 0x800706cc: The Endpoint is a duplicate'

Your sound card has stopped working and you have the following symptoms

- Complete loss of audio

- A red cross over the speaker icon in the system tray (bottom right corner) area of the screen.

- Unresponsive navigation of the Windows Control Panel causing explorer.exe to hang.

- Inability to start the 'Windows Audio' service with the error message Error 0x800706cc: The Endpoint is a duplicate.

Things I Tried that did not work

- There is no point in re-installing the driver as this will no fix the issue as this problem is not a fault of the sound card.

- The fault is with windopws system files

- SFC makes no difference

- fixing issues in the registry makes no difference

- resetting all windows services to default

- manually starting the appropriate services

Cause

The basic cause of this is that AVG has incorrectely identified windows system files as Virus and as such one or more the following happens on registry entries and files. I am not sure which, but the outcome is the same.

- a file has been cleaned - some of the file that appears as a virus has been removed but the orginal file is left remaining, just not intact

- a file has been deleted

- registry settings have been deleted

My guess is that AVG has cleaned a file incorrectely, but for some reason SFC does not detect the change when it is run.

Solution

This depends on how much messing about you have done but i will outline the solutions.

- The files have been quarantined in AVG, so just go into AVG and unquarantine all files anf things in the vault. Restore all files and settings even if you get a message that you are going to replace files or settings. This is what you want.

- If you have uninstalled AVG, Re-Install AVG and see if you still have the files in the vault and follow option 1.

- If the above does not work try running system restore too before a time when you had the issue.

I am sure AVG is aware of this issue and will fix it in newer versions of their software.

Other Resources

- Windows could not start the Windows Audio Service - Microsoft Community - Some Useful links

- Can't enable windows audio on Windows 8.1 - Super User

- Windows Faults Fixed: HOW TO FIX: Sound not working in Windows 8 - 'Error 0x800706cc: The Endpoint is a duplicate'

- Windows Audio cant be started, error 0x800706cc - Microsoft Community

- How to solve audio service not running problem+windows audio 1079 error - YouTube

- How to Fix Audio Problems on Windows 8 / Windows 8.1 - YouTube

- drivers - "The Audio Service is not running" Windows 8.1 Lenovo G500 - Super User

- Windows Audio can't be started. Error 0x800706cc

- Windows 8 audio service issues : techsupport

HP Officejet 7610 won't direct scan from the Printer to the PC

Do you have a HP Officejet 7610 A large format printer that will scan from your computer but if you try and use the console on the priner to scan you get the follwing error

The scan could not be completed due to one or more of the following reasons / The scan could not be completed due to one or more of the following issue: - Connection to the computer is lost. - The application scans on the computer is currently in use. - OCR application is not installed on the computer.

You might also come across this when the printer is working fine and then seems to loose its settings.

Solution

Uninstalling the driver and re-installing it seems to fix the issue temporarily. The key to completely fixing this issue is as follows.

- download the latest Full software package

- uninstall all the printer software including the 3rd party packages that came with the printer software, this seems to be the key because i beleieve it is the 3rd party softwares that have the daemon/monitor that waits for contact from the printer. To find out what software was installed by the printer software if you do not know is to start the install of the new software package and then select custom install. The software list that then pops up will have greyed out options against software that is already installed and thus cannot be installed. What this means is the software that you cannot install is already installed and should be removed.

- Make sure you reboot your computer after you have uninstalled the software.

- install the latest software package for the printer and to be on the safe side run as administrator whilst your antivirus and firewall is completely disabled. This makes sure that all registry settings is installed correctely

- check your USB cable is USB 2.0 rated and that the USB port you are using is supplying enough voltage.

Please note that Using the HP Connection Doctor seems to temporarily fix this issue but might perfom a permanent fix on some peoples PCs.

Other Resources

- A 'Computer Not Found' or 'Connection Error' Message Displays for HP Officejet 7610 Wide Format e-All-in-One Printer Series (H912) | HP® Support - This covers all connections types and all windows versions

- HP Print and Scan Doctor - The HP Print and Scan Doctor was designed by HP to provide users with the troubleshooting and problem solving features needed to resolve many common problems experienced with HP print and scan products connected to Windows-based computers.

Sage Software Persistently Mapped Network Drives Batch File

This a batch file i wrote for my sage installations. In sage it is important that you map a netwrok drive when using a network location for the storage of the database files. Some version of windows, especially Windows XP will constantly drop mapped drives and you would ahve to intiate them in my computer before they would work again.

This batch file forces the connections to be re-established on every boot.

net use m: "\\server\Admin Documents" /yes net use p: "\\server\Sage Payroll" /yes net use s: \\server\Accounts /yes net use t: "\\server\Tax Share" /yes net use y: "\\server\Sage Accounts Production" /yes net use z: "\\server\Sage Corporation Tax" /yes

Setup cannot continue because one or more prerequisites required to install KB2686509 failed (0x8007F0F4)

Today’s blog is going to cover some issues regarding the installation of MS12-034 (2686509). When installing this update you may encounter the following error message:

Setup cannot continue because one or more prerequisites required to install KB2686509 failed (0x8007F0F4)

Solution

Security Update KB2686509 will not install- error code 0xf0f4 - Microsoft Community

I struggled with this for days. Here is what was happening and what I did that worked.

faultykeyboard.log listed 24 entries of the form kb*.kbd

I searched and no such files exist on my computer. By running regedit and looking I found 24 abnormal looking subkeys matching the list in:

HKEY_LOCAL_MACHINE/SYSTEM/CurrentControlSet/Control/Keyboard Layouts

After carefully reviewing the potential for damage I discovered that the operating system automatically restores this section of the registery if a boot failure occurs.

I then boldly deleted all subkeys of the type *.kbd from the registry. I deleted faultykeyboard.log. I rebooted then ran the update KB2686509 and it installed and rebooted the computer.

The problem is gone. Everything works.

or try

Good tips in this thread. It ultimately led me to my solution. The problem computer here was also running a version of Windows XP modified with NLite.

I was able to resolve this problem by first opening the faulty keyboard log. On the problem computer, it was located in C:\Windows\system32\faultykeyboardlog.log.

The faultykeyboard.log file simply listed these four items:

KBDDV.DLL

KBDUSX.DLL

KBDUSL.DLL

KBDUSR.DLL

I went to a computer that I knew had an unmodified version of Windows XP Professional, copied those four DLL files from C:\Windows\system32. I then transfered them to the C:\Windows\system32 on the problem computer and re-ran the manual installation file for KB2686509 which can be downloaded at http://www.microsoft.com/en-us/download/details.aspx?id=29804.

Other Solutions

Try these if the above does not work

The itunes library file cannot be saved. you do not have enough access privileges

When trying to add, delete, or sync any music in my iTunes I receive this error. "You do not have enough access privileges for this operation. iTunes could save your music library"

Or

I keep getting an error "The iTunes library file cannot be saved. You do not have enough access privileges for this operation." in random times when I use iTunes. I said in random times because I don't get an error when I import files to the library or to my iPhone and even though I click on "Don't show this message again." I still get it after I restart my PC.

The itunes library file cannot be saved. you do not have enough access privileges

You possibly cannot update your itunes library

Solution 1

What i found whas that BT Cloud Sync had a lock on the iTunes ITL file and was always trying to sync it to the cloud. Because it was locked, iTunes could never update it and could never save it either. This can also be true for other applications that might be syncing files or backing them up.

NB 1:

In my C: Drive itunes music folder i had 900.tmp files, i have deleted these, could someone explain what these are for?

Those .tmp files means some other software has a lock on the iTunes Library.itl file. Every time you play a song, podacst, etc....itunes makes a tmp file, when it is done it renames it to iTunes Library.itl with the updated play count.

Something else has a lock on the ITL file, so itunes cannot rename it.

A common culprit is security software. If it is scanning the ITL file, tell it not to do that.

The iTunes library file cannot be saved. | Apple Support Communities

NB 2:

If you're an advanced PC user, get Process Monitor from SysInternals, Set it to monitor what is accessing iTunes Library.itl and iTunes Library.xml

http://technet.microsoft.com/en-us/sysinternals/bb896645.aspx

What should i Do?

uninstall or disable BT cloud sync. If it is not this, you should use the SysInternals method to find out what program is locking the ITL file.

Other Solutions (not tried)

- check permissions on the \My Documents\My Music\iTunes folder

- run iTunes as an administrator

- "Goto \My Documents\My Music\iTunes and right click on the iTunes Library file, select properties > then unselect Read-Only".

some times everything is set as read only -

The location of the iTunes Library file may be read-only or owned by a different user.

Default locations:

XP: C:\Documents and Settings\<login>\My Documents\My Music\iTunes

Vista: C:\Users\<login>\Music\iTunesWindows 7: C:\Users\My Music\itunes

Right click the iTunes folder and choose Properties

Look at the Attributes and see if Read-Only is checked.

Uncheck it and click OK, at the apply to all subfolders and files prompt, make sure all subfolders and files is selected and click OK.

If your iTunes library saves now you are done.

If it does not you will need to try on each directory above the iTunes directory.

Of course if you are not using the default locations you'll have to alter the path to the one you find in iTunes Edit->Preferences, Advanced tab. -

If the earlier suggestion didnt work, just delete the itunes library file "iTunes Library.itl" and re-open itunes.

Default locations for the itunes library file:

XP: C:\Documents and Settings\<login>\My Documents\My Music\iTunes

Vista: C:\Users\<login>\Music\iTunesWindows 7: C:\Users\My Music\itunes

This solved it for me... - - right click on music folder

- click on properties

- click restore defaults

- welcome back itunes - I had this same problem I am running Windows 7 Ultimate 32bit.

I found away to fix my problem

If you go to the iTunes.exe

C:\Program Files\iTunes\iTunes.exe

Right click on the iTunes.exe

select "Properties"

Click on "Security" Tab

High Light your User Name

** I did not have "Full Control"

I click on "Edit..."

High Lighted my User and check "Full Control"

Clicked "OK"

Click "OK"

And now opened my iTunes again and played my music with out getting that error anymore - I finally got this fixed on my machine. Windows 7, 64 bit.

- Turn off UAC - User Account Control

- Keep in mind this does turn off the protection provided.

- Go to Control Panel, System and Security, Change User Acount Control settings. Drag the slider down to never notify. Restart your computer.

Bingo bango, it worked! - Hey! I just solved this issue myself. I hope this helps

1. Right click over the iTunes Icon

2. Select "Properties"

3. Select Compatiblity

4. Uncheck the box that says, "Run this compatiblity in mode for.."

5. Apply

6. Ok

I really hope this helps! - check privilages of iTunes.exe in your C:\Program Files\Itunes\ or C:\Program Files(x86)\Itunes\ folder

Other Threads to Check

- iTunes Privileges Error with Windows 7 - Microsoft Community

- Trouble adding music to iTunes library or importing audio CD - Apple Support

- The iTunes library file cannot be saved. | Apple Support Communities

My Google Analytics Notes

- 1 account per website /APP / Application

- several properties ie subdomains cpanel.quantumwarp.com , demo.quantumwarp.com (you might possibly have a quantumwarp app seperate)

- but 1 account per thing is better because you can do what you want with it including moving the account to another google account. only accounts can be moved and thier permissions controlled

the layout of thes layers of analytics is confusing.

My Capacitor Notes

Answers from h.m.comp on ebay

400V 100uF 105°C electrolytic radial Capacitor

is this low ESR ?

No these are not low ESR caps.

do you have one that is, same specs. it is for a power supply in a tft monitor. i have installed this cap and the monitor is now working but i believe that it will not last unless i put a low esr one in. am i right?

Out of experience i can say that the big capacitor in power boards for LCD Monitors and TV's do rarely fail.

They are usually High temp/Long Life capacitors and usually outlive the smaller caps.

You will find the datasheet for this one here:

http://www.nichicon.co.jp/english/products/pdfs/e-pt.pdf

I do have a panasonic version of the 400v 100uf ,but again this is i high temp/long life capacitor too.

The big capacitor i swapped had spilt its guts so has definately gone.

High temp/Long Life capacitors = not ESR ?

so using this nichion capacitor should be ok?

Yes they will be ok for power supplies.I have used them many times myself.

Remote Access and Remote Desktop Software

This is my list of 3rd party Desktop sharing services/clients i have found on the internet. Some are free and some are really expensive.

- AnyDesk

- Teamviewer

- Gotomypc

- Join.me

- Avast has remote control built in. Both PCs need Avast installed

- Gotoassist

- Hamachi free

- Open VPN + RDP

- No Machine 4

- Meraki Systems Manager

- VNC

- RealVNC

- UltraVNC

- Jumpdesktop.com/free-remote-desktop

- Chrome remote desktop

- Gbridge

- Spiceworks + RDP

- Server 2003 + RDP Etc..

- Aeroadmi.com

- AMMY admin

- RDP

- Centra Stage ©

- Mikogo ©

- Skype (probably has remote desktop)

- Zoom

- Radmin

- MSP360 Connect (formerly CloudBerry Remote Desktop)

- Google Chrome

- Microsoft Assist

- Remote Utilities

- Get Free License | Remote Utilities - Get free license for business and personal use.

- Splashtop